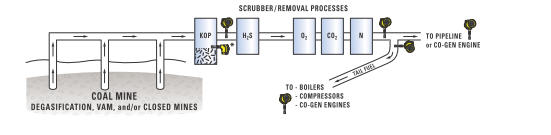

An emerging application gaining attention from stakeholders in mining operations and from environmentalists is coal mine methane recovery. It has been estimated that 8% of the world's anthropogenic methane air pollution is a by-product of coal mining. There are three major sources of coal mine methane (CMM): degasification systems (drainage) both pre-mine and gob; ventilation air (VAM); and abandon or closed mines. As technology, economics, environmental regulations and greenhouse gas reduction incentives increase, this gas is increasingly being captured and used as a fuel source. Methane gas flow meters are required to comply with regulations, to ensure efficient operation of co-gen engines or methane oxidizers, and to provide data for incentive credits.

Depending on the source application, concentration of methane in the extracted gas can be as little as 1% (e.g. VAM) to more than 20% in drainage systems. Other components in the gas include air, carbon dioxide (CO2) and/or nitrogen (N2) in various combinations depending on the site and source. Therefore proper flow meter calibration matched to the actual gas mix is critical for accurate performance. Additional considerations and challenges in this application include safe installation in an explosive atmosphere, low power consumption, low flow sensitivity and ease of installation in a variety of pipe sizes and locations.

Key Criteria For Flow Meter Selection

- Agency approved for use in Division 1 [Zone 1] hazardous environment

- Specifically calibrated to match low concentration methane gas composition

- Temperature compensated flow measurement for accuracy and repeatability in changing ambient and gas temperatures

- Easy to install

- Non-clogging, no moving parts design for low maintenance

- Wide turndown for wide flow range measuring and with low flow sensitivity

- Multi-parameter – flow rate, totalized flow and temperature in a single device

FCI thermal dispersion flow meters, in both insertion and in-line styles, are ideal for application in CMM recovery. They address all of the key criteria and solve the challenges of the application to provide an accurate, highly repeatable and cost effective solution. FCI calibration laboratory ensures a meter calibration matched to gas composition. FCI flow meters have global agency approvals on the complete instrument for installations in hazardous/explosive environments.

For line sizes larger than 2.5" [63 mm]

For line sizes 2.0" [51 mm] and smaller

* FCI Model FLT93 switches provide level detection for Knock-Out Pot (KOP) and condensate pot applications.