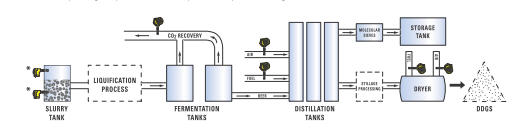

As costs of fossil fuels continue to climb and air pollution reduction regulations become more stringent, the production of ethanol fuel and fuel supplements grows. At the forefront of ethanol production is the need to continuously improve processes and reduce costs to maximize effectiveness and efficiency.

Ethanol production is a distillation process which involves boilers. Efficiency is optimized with measurement and control of air-to-fuel mixtures/ratios. The process may also utilize catalytic or thermal oxidizers to reduce emissions of greenhouse gases or VOCs. Accurate air and gas flow measurements in large pipes or duct applications are challenged by distorted flow profiles and swirls, varying air temperatures, installation costs, and accessibility for maintenance. Measuring gases vented from the process can provide information about process inefficiencies or other problems. Further, measurement and reporting may be mandated by local air pollution regulations.

Key Criteria For Flow Meter Selection

- Temperature compensated flow measurement for accuracy and repeatability in changing ambient and process gas temperatures

- Easy to install and cost effective in large diameter pipes

- Non-clogging, no moving parts design for low maintenance

- Wide turndown for accurate low and high flow rate measuring

- Multi-parameter flow rate, totalized flow and temperature in a single device

- Calibration matched to specific gas and application

- Multi-point sensing for accuracy in large pipes, stacks and ducts with distorted and/or swirling flow profiles

- Flow conditioning for limited straight-run application

FCI thermal dispersion, insertion mass flow meters in single-point and multi-point configurations for large line sizes and in-line styles for smaller line sizes provide cost effective and accurate engineering solutions throughout the ethanol process. In addition to meeting the above requirements, FCI flow meters feature robust transmitter electronics in rugged enclosures for long service life.

For line sizes larger than 2.5" [63 mm]

For line sizes 2.0" [51 mm] and smaller