Flue gases are exhausted from many processes including metals operations, chemical, food processing, petroleum processing, pharmaceutical productions, paper plants, power plants and boilers.

FCI's single-point (ST Series) or multi-point (ST102A, MT100 Series) flow meters offer accurate and cost effective solutions to flue gas flow measurement.

Companies utilizing FCI flow meters for flue gas applications include US Steel, Kraft Foods, Georgia-Pacific, Dupont, Rohm & Haas, Shijiazhuang Refinery, ELF Atochem, Kemirea Pigments, Fundia Wire, Noranda Mining, and Foster-Wheeler Energy, among others.

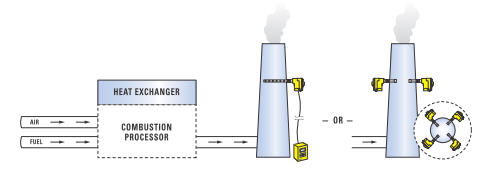

Flue gases are the general name given to the mixed composition gases that are the by-product of a combustion process. A flue is typically a large pipe, duct, stack, chimney or other venting attached to a process system such as a boiler, furnace, steam generator, oven, etc. through which waste flue gases are exhausted from the combustion process.

Depending on the process, the fuel used and efficiency, flue gases can consist of nitrogen, carbon dioxide, trace amounts of oxygen and water vapor, and environmentally sensitive pollutants such as sulfur oxides, nitrogen oxide, carbon monoxide and particulates. In addition to measuring the flow of flue gases for process control data, reporting is often mandated by Federal, Regional, and/or Local environmental air quality regulations.

Flue gas applications present several challenges in selecting the proper flow meter:

- Mixed composition gases

- Wet and/or dirty gas

- Large and difficult to access pipes

- Wide flow range and distorted, swirling flow profiles

Key Criteria For Flow Meter Selection

- Accurate and calibrated for mixed composition gases

- Low cost installation in large diameter pipes

- Single-point and multi-point solutions

- Mass flow measurement

- Non-clogging, no moving parts design for low maintenance

- Wide turndown for wide range flow measurement

- Remote mountable transmitter/electronics

- Temperature compensation

FCI thermal dispersion insertion flow meters provide a cost effective and accurate solution to flue gas flow measurement. These flow meters are designed to overcome the unique challenges of flue gas measurement and meet all of the above criteria. For line sizes up to 30 inches [760 mm], FCI single-point meters are typically applied. For larger line sizes, FCI multi-point systems provide up to 16 sensors to achieve flow averaging in large cross-sectional areas. Additionally, these FCI flow meters are direct mass flow measuring so that unlike volumetric flow techniques, there are no additional sensors to be purchased or installed to obtain mass flow.

For line sizes larger than 2.5" [63 mm]